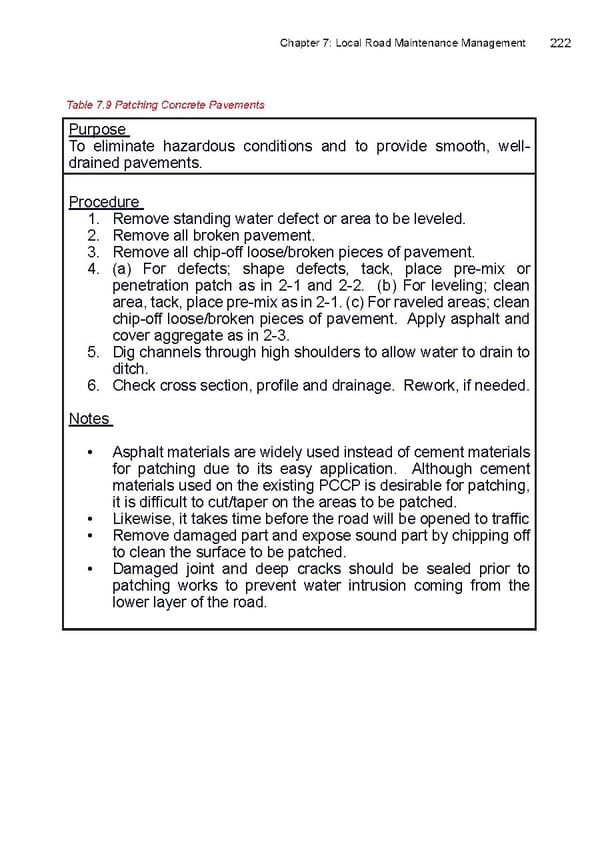

Chapter 7: Local Road Maintenance Management 222 Table 7.9 Patching Concrete Pavements Purpose To eliminate hazardous conditions and to provide smooth, well- drained pavements. Procedure 1. Remove standing water defect or area to be leveled. 2. Remove all broken pavement. 3. Remove all chip-off loose/broken pieces of pavement. 4. (a) For defects; shape defects, tack, place pre-mix or penetration patch as in 2-1 and 2-2. (b) For leveling; clean area, tack, place pre-mix as in 2-1. (c) For raveled areas; clean chip-off loose/broken pieces of pavement. Apply asphalt and cover aggregate as in 2-3. 5. Dig channels through high shoulders to allow water to drain to ditch. 6. Check cross section, proifle and drainage. Rework, if needed. Notes • Asphalt materials are widely used instead of cement materials for patching due to its easy application. Although cement materials used on the existing PCCP is desirable for patching, it is diiffcult to cut/taper on the areas to be patched. • Likewise, it takes time before the road will be opened to traiffc • Remove damaged part and expose sound part by chipping off to clean the surface to be patched. • Damaged joint and deep cracks should be sealed prior to patching works to prevent water intrusion coming from the lower layer of the road.

LRM Manual CMGP Page 221 Page 223

LRM Manual CMGP Page 221 Page 223