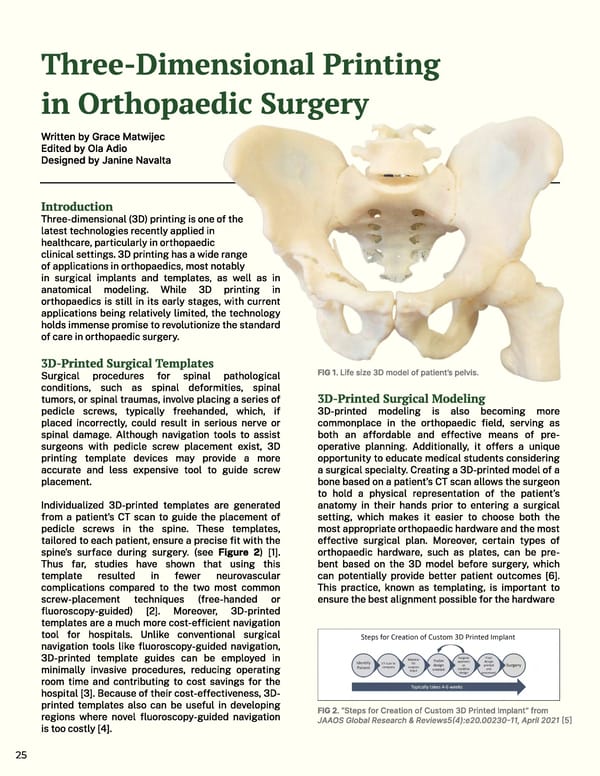

Three-Dimensional Printing in Orthopaedic Surgery Written by Grace Matwije挀 Edited by Ola Adi漀 Designed by Janine Navalta Introductio渀 Three-dimensional (3D) printing is one of the latest technologies recently applied in healthcare, particularly in orthopaedic clinical settings. 3D printing has a wide range of applications in orthopaedics, most notably in surgical implants and templates, as well as in anatomical modeling. While 3D printing in orthopaedics is still in its early stages, with current applications being relatively limited, the technology holds immense promise to revolutionize the standard of care in orthopaedic surgery㠀 3D-Printed Surgical Template猀 FIG 1. Life size 3D model of patient’s pelvis. Surgical procedures for spinal pathological conditions, such as spinal deformities, spinal tumors, or spinal traumas, involve placing a series of 3D-Printed Surgical Modelin最 pedicle screws, typically freehanded, which, if 3D-printed modeling is also becoming more placed incorrectly, could result in serious nerve or commonplace in the orthopaedic 昀椀eld, serving as spinal damage. Although navigation tools to assist both an affordable and effective means of pre- surgeons with pedicle screw placement exist, 3D operative planning. Additionally, it offers a unique printing template devices may provide a more opportunity to educate medical students considering accurate and less expensive tool to guide screw a surgical specialty. Creating a 3D-printed model of a placement.⨀ bone based on a patient’s CT scan allows the surgeon to hold a physical representation of the patient’s Individualized 3D-printed templates are generated anatomy in their hands prior to entering a surgical from a patient's CT scan to guide the placement of setting, which makes it easier to choose both the pedicle screws in the spine. These templates, most appropriate orthopaedic hardware and the most tailored to each patient, ensure a precise 昀椀t with the effective surgical plan. Moreover, certain types of spine's surface during surgery. (see Figure 2) [1]. orthopaedic hardware, such as plates, can be pre- Thus far, studies have shown that using this bent based on the 3D model before surgery, which template resulted in fewer neurovascular can potentially provide better patient outcomes [6]. complications compared to the two most common This practice, known as templating, is important to screw-placement techniques (free-handed or ensure the best alignment possible for the hardware 昀氀uoroscopy-guided) [2]. Moreover, 3D-printed templates are a much more cost-ef昀椀cient navigation tool for hospitals. Unlike conventional surgical navigation tools like 昀氀uoroscopy-guided navigation, 3D-printed template guides can be employed in minimally invasive procedures, reducing operating room time and contributing to cost savings for the hospital [3]. Because of their cost-effectiveness, 3D- printed templates also can be useful in developing FIG 2. “Steps for Creation of Custom 3D Printed Implant” from regions where novel 昀氀uoroscopy-guided navigation JAAOS Global Research & Reviews5(4):e20.00230-11, April 2021 [5] is too costly [4]. 25

Penn Healthcare Review Fall 2023 Journal— Sports Medicine Page 29 Page 31

Penn Healthcare Review Fall 2023 Journal— Sports Medicine Page 29 Page 31