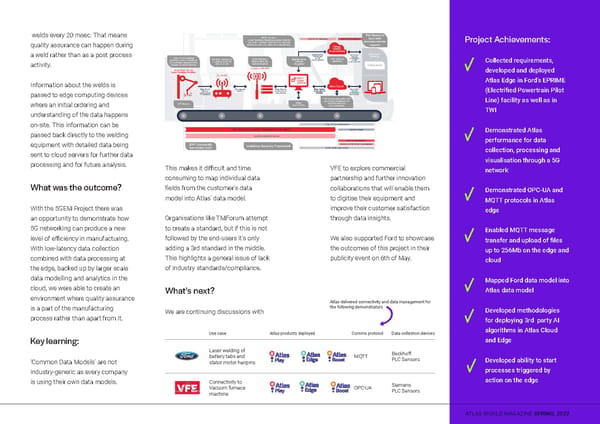

welds every 20 msec. That means Project Achievements: quality assurance can happen during a weld rather than as a post process Collected requirements, activity. developed and deployed Information about the welds is Atlas Edge in Ford’s EPRIME passed to edge computing devices (Electrified Powertrain Pilot where an initial ordering and Line) facility as well as in understanding of the data happens TWI on-site. This information can be Demonstrated Atlas passed back directly to the welding performance for data equipment with detailed data being collection, processing and sent to cloud servers for further data visualisation through a 5G processing and for future analysis. This makes it difficult and time VFE to explore commercial network consuming to map individual data partnership and further innovation What was the outcome? fields from the customer’s data collaborations that will enable them Demonstrated OPC-UA and model into Atlas’ data model. to digitise their equipment and MQTT protocols in Atlas With the 5GEM Project there was improve their customer satisfaction edge an opportunity to demonstrate how Organisations like TMForum attempt through data insights. 5G networking can produce a new to create a standard, but if this is not Enabled MQTT message level of efficiency in manufacturing. followed by the end-users it’s only We also supported Ford to showcase transfer and upload of files With low-latency data collection adding a 3rd standard in the middle. the outcomes of this project in their up to 256Mb on the edge and combined with data processing at This highlights a general issue of lack publicity event on 6th of May. cloud the edge, backed up by larger scale of industry standards/compliance. data modelling and analytics in the Mapped Ford data model into cloud, we were able to create an What’s next? Atlas data model environment where quality assurance Atlas delivered connectivity and data management for is a part of the manufacturing We are continuing discussions with the following demonstrators Developed methodologies process rather than apart from it. for deploying 3rd party AI Use case Atlas products deployed Comms protocol Data collection devices algorithms in Atlas Cloud Key learning: and Edge Laser welding of Beckhoff ‘Common Data Models’ are not battery tabs and MQTT PLC Sensors Developed ability to start stator motor hairpins industry-generic as every company processes triggered by is using their own data models. Connectivity to Siemens action on the edge Vacuum furnace OPC-UA PLC Sensors machine ATLAS WORLD MAGAZINE SPRING, 2022

Atlas World Magazine - SPRING 2022 Page 12 Page 14

Atlas World Magazine - SPRING 2022 Page 12 Page 14